— product —

customer service +86 18020721390

customer service +86 18020721390 Email:sakyzeng@foxmail.com

Mobile:+86 18020721390

Telephone:+86 18020721390

Address:Hongshan Hotel, No. 42 Hongshanhu Road, Beijie Street, Xixiu District, Anshun City, Guizhou Province

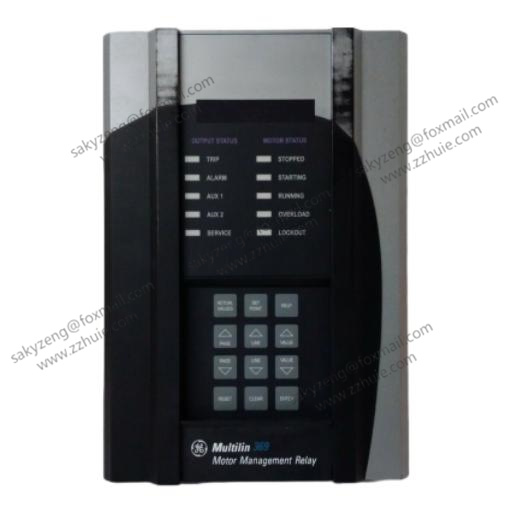

Brand: GE

Model: GE 369-HI-R-M-F-E-H-E | Motor management relay

Origin: Switzerland

Warranty: 365 days

Quality: new/second-hand

Delivery method: express delivery

product details

Related recommendations